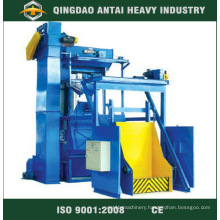

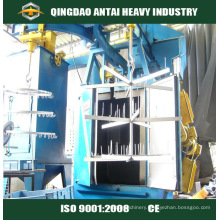

Q326c Steel Bar Derusting Machine

Basic Info

Model No.: Q326C

Product Description

Model NO.: Q326C

Fuel: Diesel

Cleanliness: Normal Cleanliness

Certification: CE

Condition: New

Producivity: 0.6-1.2t/H

End Plate Dia.: 650mm

Machine Color: Customzied

Specification: ISO Standard

HS Code: 84798190

Application: Beverage Processing

Type: Crawler Abrator

Automation: Manual

Feature: Critical Cleaning / Residue Free

Customized: Customized

Shot Blasting Machine: Rubber Belt Tumble

Power Supply: 220V,380V,440V, 600V

Trademark: C&J

Origin: China

(Q326C Abrator) Tumble Shot Blasting Machine

Packing: One set bulk packing in 1x20'FCL.

Delivery time: 45-50days.

Payment: T/T35%deposit, the balance is paid before shipment after receiving our correct machine pictures and packing photos.

This machine has been ship into Europe market for many times. It's the popular products.

Tumble belt shot blasting machines are the most universal among all shot blasters as their design makes them suitable for processing parts of different sizes in bulk loads. These types of tumble belt shot blasting machines are very easy to operate. The process starts with the loading of the parts on the belt either manually or through an automatic loading system. Once the door is closed the blasting cycle initiates. The wheels and the belt start spinning producing a continuous rotation of the parts ensuring that all components are exposed to the shot blasting stream for consistent cleaning. When the blasting process finishes, the machine stops automatically allowing the unloading of the parts to take place. Then, the operator moves the belt in the reverse direction to prepare the machine for a new load.

There have two type available: Steel apron, rubber apron. It's suitable for eliminating rust and lasting shots for those work pieces under 15kg. It could be used singly of line -mixed.

Features & benefits:

One (1) direct-drive, 8 bladed blast wheel assembly, wheel drive motor.

No pit cabinet design,

Real access door provided unrestricted access to the mill, elevator belt, lower elevator pulley, reclaim screw and lower screens.

Manganese steel roof liners and barrel head seals with cast, long time barrel head liners and in-line liners.

Front idler roller equipped with fins designed to prevent abrasive from building up under mill belt.

Screw conveyor returns abrasive and containments to the bucket elevator, the to the air wash separator.

Air wash separator with overflow to lower storage hopper.

Air cylinder operated butterfly valve for positive abrasive flow control.

Intergral discharge plate deploys when loading door is opened to direct parts into unload system.

Electrical:

Primary power requirements: 380 volts, 50Hz, 3phase

Control panel equipped with push buttons and pilot lights, emergency stop button, and mainline disconnect.

Safety Features:

Timed operation between the abrasive control valve and the door

Limit switch on the loading and rear access door to prohibit the wheel from starting when the door is opened.

Safety Signs

Options:

Programmable logic controls ( PLC )

Variable speed wheel motor

Pivot loader (mechanical and or hydraulic operation)

dust collector can be plated bag with vibrating mechanism or hand shaking or pulse valve

Dust collector can be cartridge filter with pulse v

Special design based on the requirements of customer is available.

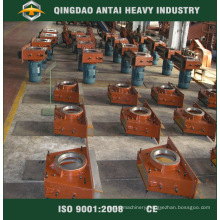

We have special crafts on hot treating and wear-resisting parts, which can supply varies of wear-castings, including blade, control cage, impeller, guard board etc. We provide high quality abrasion-resistant fittings on demand of customers and complying with the standards and requirements of the country where the machines are used. Our proof wear-resisting parts have received the good comment from home and abroad. We also produce the products which can replace the spare parts needing import in our homeland.

Our company has be granted CE, ISO9001 and SGS etc.

Our products are sold to throughout China and exported to many countries, like Australia, Bulgaria, India, Russia, Turkey, Vietnam, Mexico, Czech, Holand, Finland, Iran, Philippines, Indonesia etc.

With professional test equipment in our company, we can test electric system and parts in various voltage and Hertz worldwide, the test range is 0-600V, 45-60Hz, passed the test, it can ensure our machine working normally under specific power at the user side.

| Technical data | |||||

| series | model | Q326C Rubber belt | Q3210 Rubber belt | ||

| 1 | productivity | T/h | 0.6-1.2 | 1.5-2.5 | |

| 2 | First shot capacibility | kg | 200 | 600 | |

| 3 | Max. component weight | kg | 10 | 30 | |

| 4 | End plate diameter | mm | Φ 650 | Φ 1000 | |

| 5 | Max. batch volume | m | 0.15 | 0.3 | |

| 6 | Shot blasting capacibility | kg/min | 100 | 250 | |

| 7 | Air required for dust colector | m 3 /h | 2200 | 5000 | |

| 8 | Power | kw | 12.6 | 24.3 | |

| 9 | Size of the machine | mm | 3681× 1650× 5800 | 3972× 2600× 4768 | |

- Please do not hesitate to contact us for more details or data sheets, all other questions would be fully welcomed too.

- Latest MACHINERY CATALOGUES are available now! Download them on our official website or directly contact us.

- CJ Machinery always insist on the concept of providing our customers the most enjoyable metal working experiences. Every need or request would be answered at our best considering customer's greatest interests.

- CJ Machinery values each relationship among our worldwide customers and hopes every unique requirement of our customers could be satisfied.

Contact us if you need more details on Shot Blasting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tumble Shot Blasting Machine、Abrator. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Shot Blasting Machine > Tumble Shot Blasting Machine

Other Products

Hot Products

High Speed CNC Wire Cut Discharge EDM (DK7740)Universal Turret CNC Milling Machine (XK6325)M1420 X500/750 Universal Cylindrical External Grinding MachineRadial Drilling Machine (Z3032X9/10)Upright Drilling Machine (Z5032C Z5040C Z5045C)Lathe - Mill - Drill (3- in- 1) Multi Purpose Combined Machine (WMP250V, WMP280V, WMP290V)Centre Length 1000mm Bench Heavy Lathe Machines (GH1440K)CNC Lathe Machine (CK6136/CK6140)Hook Shot Blasting Machine (Q378E)Shot Blast Cleaning Machine Crawler AbratorUnviersal Turret Milling Machine (X6325, X6325A, X6325B, X6325C, X6325D)Heavy Duty Lathe Tornos 1000mm 1500mm 2000mm 3000mm (CY6280)Surface Grinding Machine (M820) Table Size 200x500mmM618A Manual Surface Grinding Machine Table Size 400x180mm (M618A)Full Auto PLC Hydraulic Surface Grinding Machine (SGA4080AHD) Table Size 400x800mmQ326c Dia. 650mm Tumble Shot Blasting Cleaning Machine