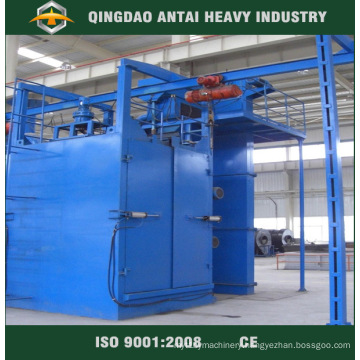

Hanger Type Shot Blasting Machine for Medium Metal Parts

Basic Info

Model No.: QD37

Product Description

- Model NO.: QD37

- Color: Named Color

- Energy: Electricity

- Physical Machine Type: Mechanical Cleaning Method

- Machine Type: Abrator

- Cleaning Process: Shot Cleaning

- Trademark: ANTAI

- Origin: Shandong

- Certification: ISO

- Blast Wheel: 2-6 Nos

- Style: Swing Style

- Usage: Metallurgical Industry

- Clean Type: Abrasive Blasting

- Principle: Electronic

- Specification: CE

- HS Code: 8424

Hook shot blasting machine is widely used in foundry plant, forging plant.metal processing.

The double hook or Y track rail shot-blasting machines are the most versatile in terms of typical employment and size of the materials to be treated. Moreover the motorised hoists installed on the overhead conveyor allow the lifting of very high loads. The customer can choose the size and loading capacity of the machine according to the parts to be shot-blasted.

The hook type shot blasting machine is designed to increase the performance of the hook type machines by keeping the turbines continuously running.

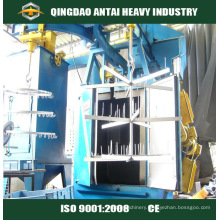

The hook inside the blasting machine, once in position, starts to rotate on its axis and move back and forward in front of the turbines (mounted on one side of the machine). These combined movements ensure the complete shot-blasting of the parts external surface.

The customer can choose the size and loading capacity of the machine according to the parts to be shot-blasted.

Depending on the height of the machine, the installation may require a pit. The shot blasting unit is supplied complete with a self-cleaning dry cartridges dust collector.

This type of Shot Blasting Machine can be designed and produced according to your parts dimension, weight and productivity individually.

FAQ

1.What is your parts going to be blasted?

It is better you tell us the parts going to be blasted, then we can select the suitable machine for you.

2.What is the max and min dimension of your parts?

Yes, if you can let us know the dimension, we can design proper shot blastingmachine size for you to reduce the investment money.

3. How many pieces of your parts blasted per day in 8 hours?

Yes, according to your productivity requirement, we design suitable capcity machine for you.

4. What is the lead time of our shot blasting machine?

For small machines, usually we have stock in factory.

Big machines, the lead time is usually 45 to 60 days.

5. Are the machine tested before shipping?

Yes, all of our machines are tested before shipment.

6.What's your quality guarantee?

Quality guarantee time is one year.

7. Are you able to give Installation and commissioning overseas ? How long will it take?

Yes, we supply overseas service, but customer needs to pay for the engineers flight tickets and hotel, food.

Small machine usually takes 2 to 4 days.

Big machine usually takes 20-25 days.

Contact us if you need more details on Shot Blasting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Abrasive Blasting Machine、sand blasting machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : hook type shot blasting machine

Premium Related Products

Other Products

Hot Products

High Speed CNC Wire Cut Discharge EDM (DK7740)Universal Turret CNC Milling Machine (XK6325)M1420 X500/750 Universal Cylindrical External Grinding MachineRadial Drilling Machine (Z3032X9/10)Upright Drilling Machine (Z5032C Z5040C Z5045C)Lathe - Mill - Drill (3- in- 1) Multi Purpose Combined Machine (WMP250V, WMP280V, WMP290V)Centre Length 1000mm Bench Heavy Lathe Machines (GH1440K)CNC Lathe Machine (CK6136/CK6140)Hook Shot Blasting Machine (Q378E)Shot Blast Cleaning Machine Crawler AbratorUnviersal Turret Milling Machine (X6325, X6325A, X6325B, X6325C, X6325D)Heavy Duty Lathe Tornos 1000mm 1500mm 2000mm 3000mm (CY6280)Surface Grinding Machine (M820) Table Size 200x500mmM618A Manual Surface Grinding Machine Table Size 400x180mm (M618A)Full Auto PLC Hydraulic Surface Grinding Machine (SGA4080AHD) Table Size 400x800mmQ326c Dia. 650mm Tumble Shot Blasting Cleaning Machine