Die Cast Die /Casting Mold /Mould /Casting Mould/Castings

Basic Info

Model No.: OEM

Product Description

Die Cast Die /Casting Mold /Mould /Casting Mould/Castings

CNC Machining, CNC Machining CNC processing refers to processing in nc Machining tools.Index of the CNC control machine tool controlled by nc programming language, usually in the form of G code.Nc machining G code what language told CNC machine tool The cartesian coordinates, and controls the tool feed rate and spindle speed, as well as the tool changer, coolant, etc.Nc machining relative manual processing has great advantages, such as CNC machining to produce parts very precise and repeatability.Nc machining process can produce manual can't complete with complex shape parts.Nc machining technology has been widely adopted, most of the machining with CNC processing ability, the typical machining workshop, the most common way of nc machining with CNC milling, CNC and CNC EDM wire cutting, EDM wire cutting cut).For nc milling tool is called numerical control Milling Machine or numerical control Machining Center.

Basic Introduction

Die casting, die casting machine, die casting materials are three main factors for die casting production. The die casting technology is the synthetically use of these three elements organically, make can steadily and rhythmically to efficiently produce appearance and inner quality, size meet the requirements of the drawings and high quality casting process.

Die casting alloy is mainly used by non-ferrous alloy, as for the black metal (steel, iron, etc.) due to problems such as mould material, use fewer. And aluminum alloy is used more widely in the non-ferrous alloy, then the zinc alloy.

About our service

We are a professional stamping moulding and Tooling manufacturer.1. High Quality Molds at Competitive Pricing

2. On Time Delivery3. Disigning the most economical solutions to match clients's budget.

4. Provide stamping Molding Solutions to Our Customers including 2D and 3D Product Development , Inspection tools and Fixture ,Design and Manufacture

5. 24 Hours On Call- Mail prompt reply

Mold process

| NM | NAME | TYPE | QTY |

| 1 | Precision engraving machine | | 3 |

| 2 | CNC Machining Center | | 8 |

| 3 | CNC lathes | | 3 |

| 4 | Normally lathes | | 1 |

| 5 | Milling machine | | 2 |

| 6 | Grinder | | 3 |

| 7 | Radia Drilling | | 3 |

| 8 | Line Cutting Machine | | 3 |

| 9 | CNC sparks machine | | 3 |

| 10 | Die spotting machine | 200T | 1 |

| 11 | Saw Machine | | 2 |

| 12 | Tappers machine | | 20 |

| 13 | 3 cordinate measuring machine | | 1 |

| 14 | Projection machine | | 1 |

| 15 | All kinds gauges | | 1aet |

| 16 | Spectrimeter | | 1 |

| 17 | Faw detector | | 1 |

| 18 | Die casting machine | 1000t | 1 |

| 19 | Die casting machine | 800t | 1 |

Mold manufacturing line

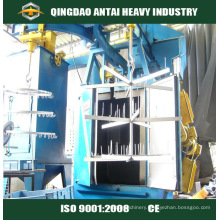

JIN HAN MOULD Main based in the casting molds , with product , mold design , manufacturing and casting production as a whole , the company has whole set modern and high-precision , high-speed processing eqipments . such as ; high speed CNC, CNC machining centre , deep hole drilling , low-middle-high speed line cuttung machine , EDM, die spotting machine , etc.

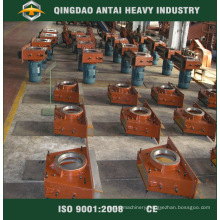

Part of the mold product display

The better quality is our unceasing pursuit , The outstanding quality is for our customer satisfaction

Product Categories : Casting Mould And Castings